Benefits of Ribbed or Waffle Slab System

- Concrete Cost Estimator

- Concrete Continuous Footing

- Landscape Bidding and Estimating

- Construction Cost Estimating

- Concrete and steel cost estimation

- Construction Cost Estimate Breakdown

- Construction Estimating Worksheet

- Home Construction Cost Estimate

- Estimate Pricing Sheet

- Sheet for General Contractor

- Construction Cost Estimate

- Labor Materials Cost Estimator

- Masonry Estimating Sheet

- Sheet for Building Contractor

- Construction Schedule Bar chart

- General Cost Estimator Sheet

- General Construction Estimate

- Building and Road Estimating Sheet

- Detailed expense estimates

- Door and Window Takeoff Sheet

- General Construction Cost Estimating Sheet

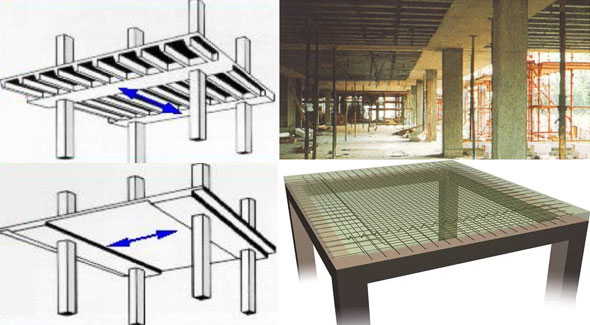

Ribbed and waffle slabs stand for a lighter and harder slab with regard to an identical flat slab which minimize the span of foundations. They create a very good form of construction where problem may occur due to slab vibration, as for instance laboratories and hospitals.

Ribbed slabs are formed with wide band beams running among columns having thin ribs stretching the orthogonal direction. Generally, the ribs and the beams contain the equivalent depth. The system is finished with a thin topping slab.

Waffle slabs are deeper as compared to the similar types of ribbed slab. Waffle slabs contain a thin topping slab and narrow ribs stretching in both directions among column heads or band beams. The column heads or band beams contain the equivalent depth as the ribs.

This type of construction is not frequently used due to the high formwork costs and poor fire rating. A 120-mm-thick slab containing a minimum rib thickness of 125 mm for continuous ribs is needed to obtain a 2-hour fire rating.

A rib thickness in excess of 125 mm is normally needed to adjust tensile and shear reinforcement. Ribbed slabs are ideal for medium to heavy loads and extent reasonable distances. They are very hard and specifically are very stiff and particularly appropriate where the soffit is uncovered.

Slab depths generally differ from 75 to 125 mm and rib widths from 125 to 200 mm. Rib spacing of 600 to 1500 mm should be utilized. The overall depth of the floor generally differs from 300 to 600 mm with overall spans of up to 15 m if reinforced, higher if post-tensioned.

Also Read: Ribbed and Waffle Slabs Construction

As the ribs are provided to the soffit of the slab, it minimizes the quantity of concrete and reinforcement as well as the weight of the floor. The saving of materials will be offset with the complication in formwork and arrangement of reinforcement.

The complexity in formwork is reduced with the utilization of standard, modular, reusable formwork, generally build with polypropylene or fibre glass and with tapered sides to facilitate stripping.

For ribs at 1200-mm centres (to adapt standard forms) the inexpensive reinforced concrete floor span ‘L’ is approximately D x 15 for a single span and D x 22 for a multi-span, where D stands for the overall floor depth. The one-way ribs are generally designed as T-beams, often stretching in the long direction. A solid drop panel is necessary at the columns and load bearing walls for shear and moment resistance.

Benefits:

• Savings on weight and materials

• Considerably light and cost-effective due to foundation costs and longer spans.

• Attractive soffit appearance when uncovered

• Inexpensive when reusable formwork pans are applied

• Vertical penetrations among ribs are simple.

• Less construction time.

• Fairly slim floor depths

• Greater vibration control

• Long lasting finishes

• Suitable for services integration

• Strong fire resistance capacity

- Application of concrete calculator

- Roofing Calculator can streamline the roof estimating process

- House construction cost calculator

- Engineering column design excel spreadsheet

- Material Estimating Sheet with Excel

- Materials List and Cost Estimate Worksheet

- Concrete Slab Estimating Calculator Sheet

- Common types of foundations for buildings

- Online calculation of construction materials

- Estimating with Excel for the Small Contractor

- Concrete Beam Design Spreadsheet

- Virtual Construction Management app for construction

- Autodesk’s Project Skyscraper

- Reed Construction’s Reed Insight

- Manage your construction project documentation

- Costimator, the popular cost estimating software

- On Center Software for construction professionals

- Free Construction Estimating Software

- Plumbing Calc Pro

- Cost Estimate Worksheet

- HVAC Piping Quantity Takeoff Worksheet

- Construction Estimating Software Sheet

- Estimate Cost Templates

- Construction Punch List

- Construction cost estimating template consisting estimating basic

- Gantt Chart Template for Excel

- Download Civil Engineering Spreadsheets with Verification

- The Building Advisor Estimating and Budgeting Worksheet

- Spreadsheet for design of concrete bridge

- Construction Estimating Software Free