Some useful tips on reinforcing steel placement

- Concrete Cost Estimator

- Concrete Continuous Footing

- Landscape Bidding and Estimating

- Construction Cost Estimating

- Concrete and steel cost estimation

- Construction Cost Estimate Breakdown

- Construction Estimating Worksheet

- Home Construction Cost Estimate

- Estimate Pricing Sheet

- Sheet for General Contractor

- Construction Cost Estimate

- Labor Materials Cost Estimator

- Masonry Estimating Sheet

- Sheet for Building Contractor

- Construction Schedule Bar chart

- General Cost Estimator Sheet

- General Construction Estimate

- Building and Road Estimating Sheet

- Detailed expense estimates

- Door and Window Takeoff Sheet

- General Construction Cost Estimating Sheet

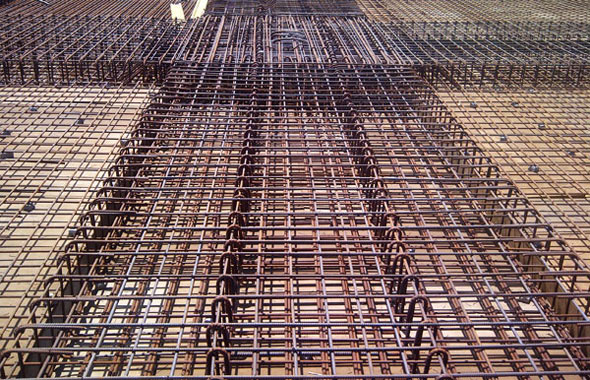

In big construction projects, it is crucial to position the reinforcing steel in exact location and retain it there throughout concrete placement. Reinforcement should be arranged as illustrated on the placing drawings. In the drawings, the number of bars, bar lengths, bends, and positions are specified by the detailer.

Cover: Proper placement of reinforcing steel is required to attain exact amount of concrete cover—the amount of concrete among the reinforcing steel and the surface of the concrete member. The main objective of the cover is to safeguard reinforcing steel from corrosion.

Cover is also essential to make sure that the steel is tied to the concrete efficiently to get its strength. The necessities for minimum cover are generally provided in the project specifications or illustrated on the drawings. If minimum cover is not indicated, the minimum cover for cast-in-place concrete is stated by the ACI 318 Building Code.

Placement: The design of the structure is dependent on keeping the steel in the exact location. Imperfect reinforcing steel placement results in collapsing of structures. As for instance, reducing the top bars or elevating the bottom bars by ½ inch in excess of that indicated in a 6-inch-deep slab could minimize its load-bearing strength by 20%.

Arranging reinforcement at the top of a layer of fresh concrete and then pouring more on top is not a suitable process for positioning. The reinforcing bar supports which are built up with steel wire, precast concrete, or plastic should be applied. Chairs and supports are attainable in different heights to support particular reinforcing bar sizes and positions. Usually, plastic accessories are cost-effective as compared to metal supports.

Reinforcing steel must be attached with support so that bars are not dislocated throughout construction activities and concrete placement. It is generally done with tie wire. Tie wire is available in 3- or 4-pound coils.

Wires are arranged in a wire holder or a reel is suspended from the worker's belt for ease of use. The wire is generally 16½- or 16-gauge black, soft, annealed wire, although 15- or 14-gauge wire is required for bigger reinforcement to retain the exact position of the rebar. Various tie types (ties are mainly wire twists for attaching intersecting bars), ranging from snap ties to saddle ties, are utilized in the concrete reinforcing industry.

PVC ties are recommended for tying epoxy-coated bars (available from American Wire Tie). Proprietary snap-on ties like Speed-Clip Rebar Tie can also be applied. It is a simple device that connects the rebar in parallel or at any angle manually devoid of any tools.

While tying bars, it is not necessary to tie every intersection—every fourth or fifth is generally ample. More ties are required when there is chance for displacement of the steel throughout concrete placement. Ensure to retain the ends of the tie wires ahead of the surface of the concrete where they could rust. For preassembled mats or reinforcing steel, tie adequate intersections to make the assembly stiff enough for placing—usually every intersection around the exterior and every other in the middle of the mat. Tack welding the intersections is not generally allowed since it minimizes the cross section of the bars.

To get information on tolerances on placement, go through the following link concreteconstruction.net

- Application of concrete calculator

- Roofing Calculator can streamline the roof estimating process

- House construction cost calculator

- Engineering column design excel spreadsheet

- Material Estimating Sheet with Excel

- Materials List and Cost Estimate Worksheet

- Concrete Slab Estimating Calculator Sheet

- Common types of foundations for buildings

- Online calculation of construction materials

- Estimating with Excel for the Small Contractor

- Concrete Beam Design Spreadsheet

- Virtual Construction Management app for construction

- Autodesk’s Project Skyscraper

- Reed Construction’s Reed Insight

- Manage your construction project documentation

- Costimator, the popular cost estimating software

- On Center Software for construction professionals

- Free Construction Estimating Software

- Plumbing Calc Pro

- Cost Estimate Worksheet

- HVAC Piping Quantity Takeoff Worksheet

- Construction Estimating Software Sheet

- Estimate Cost Templates

- Construction Punch List

- Construction cost estimating template consisting estimating basic

- Gantt Chart Template for Excel

- Download Civil Engineering Spreadsheets with Verification

- The Building Advisor Estimating and Budgeting Worksheet

- Spreadsheet for design of concrete bridge

- Construction Estimating Software Free