Brief overview of standard components of Bridge

- Concrete Cost Estimator

- Concrete Continuous Footing

- Landscape Bidding and Estimating

- Construction Cost Estimating

- Concrete and steel cost estimation

- Construction Cost Estimate Breakdown

- Construction Estimating Worksheet

- Home Construction Cost Estimate

- Estimate Pricing Sheet

- Sheet for General Contractor

- Construction Cost Estimate

- Labor Materials Cost Estimator

- Masonry Estimating Sheet

- Sheet for Building Contractor

- Construction Schedule Bar chart

- General Cost Estimator Sheet

- General Construction Estimate

- Building and Road Estimating Sheet

- Detailed expense estimates

- Door and Window Takeoff Sheet

- General Construction Cost Estimating Sheet

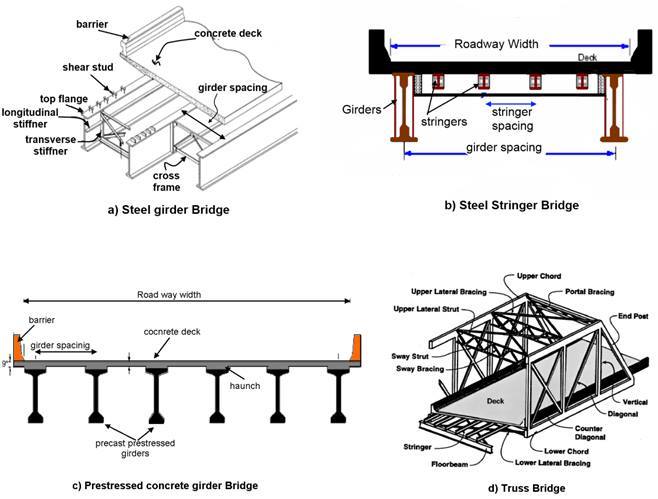

Steel Girder Bridge: After choosing the bridge type, the designer then proceeds to the complete design of the bridge. Now-a-days, most of the steel bridges are created with steel girders combined with concrete bridge decks. Here girders are utilized for providing support to the deck.

The main three parts of a bridge are : the foundation (abutments and piers), the superstructure (girder, truss, or arch), and the deck. In recent girder steel bridges, the shapes generally used are plate girders and box-girders.

The term "girder" is often used interchangeably with "beam" in reference to bridge design. However, some authors define beam bridges slightly differently from girder bridges.

The word "girder" is usually used to denote a steel beam. In a beam or girder bridge, the beams are liable for transmitting the load down to the foundation. Because of properties of inertia, the height of a girder is most crucial as it can impact its load capacity. In order to construct a deeper beam, there should be extensible spans, more traffic, or wider spacing of the beams. In truss and arch-style bridges, the girders are the key components which provide main support for the deck, but the load is transmitted via the truss or arch to the foundation.

Steel Stringer Bridge: The steel stringer alias multi-beam bridge type includes of a sequence of parallel steel beams providing support to a deck, generally made with wood planks or reinforced concrete. The steel stringer bridge generally utilizes steel beams produced through passing a steel bar amid rollers for generating a section similar to I-shape.

Prestressed concrete girder bridges: These types of bridge are most economical. These are built up with high quality materials to support manufacturing tolerances. In these types of bridges traffic loads cause only negligible stresses.

Prestressed concrete girder bridges necessitate least lead times as these are locally manufactured in standard shapes and sizes. The precast components can be easily fabricated in any weather. The deck girders are connected to the substructure with simple connections.

Formwork for the superstructure is removed while the tops of girders are arranged concurrently to produce the entire deck slab. Ties connecting adjoining units often include a grouted keyway and welded or transverse post-tensioned connections.

Truss Bridge: A truss bridge belongs to a bridge and its load-bearing superstructure is constructed witha truss, a structure of allied elements which produce triangular units. The allied elements (typically straight) may appear as stressed from tension, compression, or sometimes both concerning dynamic loads. A truss bridge is cost-effective to build up as it utilizes the materials in an efficient manner. The basic shape of a truss bridge appears to be a right triangle, with the hypotenuse stretching to the abutments. There are two identical trusses at each of the road sides.

- Application of concrete calculator

- Roofing Calculator can streamline the roof estimating process

- House construction cost calculator

- Engineering column design excel spreadsheet

- Material Estimating Sheet with Excel

- Materials List and Cost Estimate Worksheet

- Concrete Slab Estimating Calculator Sheet

- Common types of foundations for buildings

- Online calculation of construction materials

- Estimating with Excel for the Small Contractor

- Concrete Beam Design Spreadsheet

- Virtual Construction Management app for construction

- Autodesk’s Project Skyscraper

- Reed Construction’s Reed Insight

- Manage your construction project documentation

- Costimator, the popular cost estimating software

- On Center Software for construction professionals

- Free Construction Estimating Software

- Plumbing Calc Pro

- Cost Estimate Worksheet

- HVAC Piping Quantity Takeoff Worksheet

- Construction Estimating Software Sheet

- Estimate Cost Templates

- Construction Punch List

- Construction cost estimating template consisting estimating basic

- Gantt Chart Template for Excel

- Download Civil Engineering Spreadsheets with Verification

- The Building Advisor Estimating and Budgeting Worksheet

- Spreadsheet for design of concrete bridge

- Construction Estimating Software Free