Some vital check lists for plastering work

- Concrete Cost Estimator

- Concrete Continuous Footing

- Landscape Bidding and Estimating

- Construction Cost Estimating

- Concrete and steel cost estimation

- Construction Cost Estimate Breakdown

- Construction Estimating Worksheet

- Home Construction Cost Estimate

- Estimate Pricing Sheet

- Sheet for General Contractor

- Construction Cost Estimate

- Labor Materials Cost Estimator

- Masonry Estimating Sheet

- Sheet for Building Contractor

- Construction Schedule Bar chart

- General Cost Estimator Sheet

- General Construction Estimate

- Building and Road Estimating Sheet

- Detailed expense estimates

- Door and Window Takeoff Sheet

- General Construction Cost Estimating Sheet

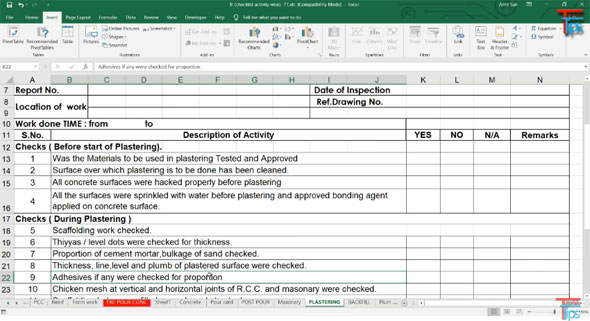

While doing plastering work, consideration should be given on the following check list.

This checklist is created in the excel format. In the head section of the check list, there are several items like Project Number, Client’s Name, Report No., Location Of Work, Inspection Date, Ref. Drawing No., Starting And Completion Date Of Work etc.

In body part, there exist items like serial number, description of activity and remarks.

The following points should be considered prior to commencement of plastering :-

The materials which will be applied in plastering should be examined properly and sanctioned.

Surface should be cleansed over which the plastering will be applied.

All the concrete surfaces should be slashed perfectly prior to the commencement of plastering.

All the surfaces should be sprayed with water prior to commencement of plastering and sanctioned bonding agent on concrete surface.

The following points should be examined throughout plastering work :-

Scaffolding work (where the labors stand) should be checked properly.

Thiyyas/level dots should be examined for thickness. As for example, if the thickness of the plaster is 10 mm, then a dot made of cement should be provided on the wall and the plastering thickness should not go beyond that.

Also Read: How to find out the quantity of cement and sand in plastering work

The ratio of cement, mortar (sand & cement mixing), bulkage (moisture content in dry sand) of sand should be examined properly.

The density, line, level and plumb of plastered surface should be examined properly.

If any adhesive is used, it should be checked that weather it is included in the plaster or not.

If any chicken mesh (a metal lath to hold cement or plaster) at vertical and horizontal joints of RCC and masonry is used, it should also be checked.

Check to fill the scaffolding holes perfectly.

Curing work after adequate consolidation of plastered surface is performed and examined.

The company engineer and the engineer provided by the client should check this lists thoroughly.

Video Source: Tutorials Tips

- Application of concrete calculator

- Roofing Calculator can streamline the roof estimating process

- House construction cost calculator

- Engineering column design excel spreadsheet

- Material Estimating Sheet with Excel

- Materials List and Cost Estimate Worksheet

- Concrete Slab Estimating Calculator Sheet

- Common types of foundations for buildings

- Online calculation of construction materials

- Estimating with Excel for the Small Contractor

- Concrete Beam Design Spreadsheet

- Virtual Construction Management app for construction

- Autodesk’s Project Skyscraper

- Reed Construction’s Reed Insight

- Manage your construction project documentation

- Costimator, the popular cost estimating software

- On Center Software for construction professionals

- Free Construction Estimating Software

- Plumbing Calc Pro

- Cost Estimate Worksheet

- HVAC Piping Quantity Takeoff Worksheet

- Construction Estimating Software Sheet

- Estimate Cost Templates

- Construction Punch List

- Construction cost estimating template consisting estimating basic

- Gantt Chart Template for Excel

- Download Civil Engineering Spreadsheets with Verification

- The Building Advisor Estimating and Budgeting Worksheet

- Spreadsheet for design of concrete bridge

- Construction Estimating Software Free