Importance of providing crank bars in slabs and beams

- Concrete Cost Estimator

- Concrete Continuous Footing

- Landscape Bidding and Estimating

- Construction Cost Estimating

- Concrete and steel cost estimation

- Construction Cost Estimate Breakdown

- Construction Estimating Worksheet

- Home Construction Cost Estimate

- Estimate Pricing Sheet

- Sheet for General Contractor

- Construction Cost Estimate

- Labor Materials Cost Estimator

- Masonry Estimating Sheet

- Sheet for Building Contractor

- Construction Schedule Bar chart

- General Cost Estimator Sheet

- General Construction Estimate

- Building and Road Estimating Sheet

- Detailed expense estimates

- Door and Window Takeoff Sheet

- General Construction Cost Estimating Sheet

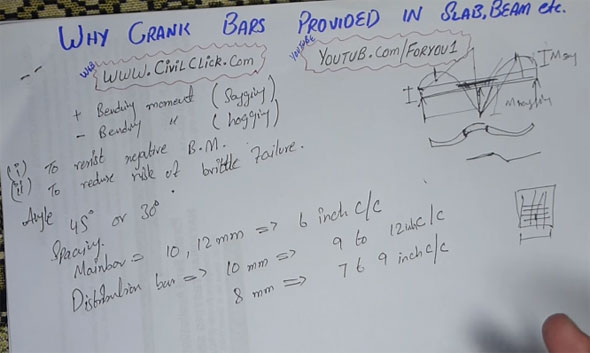

In this video tutorial, brief explanation is given on the importance of setting up crank bars alias bent up bars in slabs and beams. Besides, learn types of bending moments occurred in slabs and beams.

In a slab there are two types of bending moment i.e. positive bending moment alias sagging and negative bending moment alias hogging. Due to negative bending moment, slabs bend and cracking occur. In order to resist the possibility for collapsing of building, crank bars are provided.

Cranks bars are mainly utilized for saving of materials. Usually, for fixed ended Slabs positive (sagging) moments exist at the mid span and negative (hogging) moments at the supports.

Therefore, bottom steel is necessary at the mid span and top steel withstands negative moments at the supports. Crank bars are arranged to get the steel on the top at supports because bottom steel is not generally essential at the supports (only nominal steel is adequate at the supports).

In brief, crank bars are mainly provided for the following reasons :-

To withstand negative bending moment

To withstand the shear force that is larger at supports

To lessen the risk of brittle failure of slab-column connection

The area with 0 shear force, maximum positive bending moments occur whereas the area with maximum shear force, maximum negative bending moments occur.

The angle of the crank bars should vary among 30 degree to 45 degree if shallow beams are used there.

Spacing in crank bars depend on thickness and span of the slabs. Usually, if main bars with thickness 10 or 12 mm are used in slabs, then there should be 6 inch center to center spacing.

If distribution bars with thickness 10 mm are used in slabs, there should be 9 to 12 mm center to center spacing.

If distribution bars with thickness 8 mm are used in slabs, there should be 7 to 9 mm center to center spacing.

When bent up bars are arranged, the strength and deformation strength of slabs with bent up bars compared to slabs exclusive of bent up bars is adequately raised.

To get more information on crank bars, watch the following video tutorial.

Video Source: F&U-FORYOU

- Application of concrete calculator

- Roofing Calculator can streamline the roof estimating process

- House construction cost calculator

- Engineering column design excel spreadsheet

- Material Estimating Sheet with Excel

- Materials List and Cost Estimate Worksheet

- Concrete Slab Estimating Calculator Sheet

- Common types of foundations for buildings

- Online calculation of construction materials

- Estimating with Excel for the Small Contractor

- Concrete Beam Design Spreadsheet

- Virtual Construction Management app for construction

- Autodesk’s Project Skyscraper

- Reed Construction’s Reed Insight

- Manage your construction project documentation

- Costimator, the popular cost estimating software

- On Center Software for construction professionals

- Free Construction Estimating Software

- Plumbing Calc Pro

- Cost Estimate Worksheet

- HVAC Piping Quantity Takeoff Worksheet

- Construction Estimating Software Sheet

- Estimate Cost Templates

- Construction Punch List

- Construction cost estimating template consisting estimating basic

- Gantt Chart Template for Excel

- Download Civil Engineering Spreadsheets with Verification

- The Building Advisor Estimating and Budgeting Worksheet

- Spreadsheet for design of concrete bridge

- Construction Estimating Software Free