How to perform Steel Reinforcement Work in Building Construction

- Concrete Cost Estimator

- Concrete Continuous Footing

- Landscape Bidding and Estimating

- Construction Cost Estimating

- Concrete and steel cost estimation

- Construction Cost Estimate Breakdown

- Construction Estimating Worksheet

- Home Construction Cost Estimate

- Estimate Pricing Sheet

- Sheet for General Contractor

- Construction Cost Estimate

- Labor Materials Cost Estimator

- Masonry Estimating Sheet

- Sheet for Building Contractor

- Construction Schedule Bar chart

- General Cost Estimator Sheet

- General Construction Estimate

- Building and Road Estimating Sheet

- Detailed expense estimates

- Door and Window Takeoff Sheet

- General Construction Cost Estimating Sheet

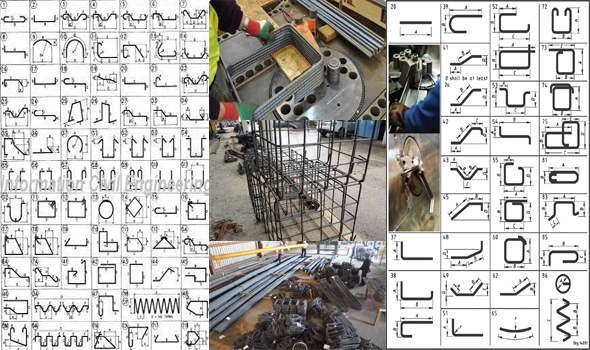

Cutting and Bending of Reinforcement: If Cold worked bars and hot rolled high yield bars are already bent they can’t be straightened or bent further. If it is required to bend mild steel reinforcement produced from the concrete, the inner radius of bend should not remain below twice the diameter of the bar.

Heating of bars is not allowed. An authorized bending machine should be used to make all bending cold. To complete this task, only expert steel benders and fixers should be appointed.

Welding of Reinforcement: While fabricating reinforced steel frame and netting, if there are no particular needs for designing, these standards should be maintained:

• For round and plain steel, welding should be at all joint point

• For edged steel, welding should be at all joint points on the two boundary lines. The other remaining points should be welded at the middle on the line which missed one line by one line consecutively.

• For reinforced steel beam frame, welding should be at all the joint points.

The welding points must fulfill these constraints:

• The surfaces are flat devoid of burns, interruption points, fractional shrinkage and foam.

• Make sure all the welding height and length maintain the designing standard.

The welding joints must be examined by types and plots. Each plots include 100 joints or 100 reinforced steel frame and netting. These plots will be examined by the followings standards:

• Each plot, 5% of the products but not below 5 samples for examining the dimensions and 3 samples for examining pulling and 3 samples for examining bending.

Adjusting Reinforcement: The quantity, sizes, form, positions and spacing of all steel reinforcement bars must be complied with the Drawings. Authorized manual or power operated cutters should be used to make all cutting and trimming of bars and wires. Welding of reinforcement is not allowed apart from special situations when it is sanctioned by the Engineer. Reinforcement produced from work already concreted must not be bent out of its exact position for any purpose, if not sanctioned by the Engineers, and should be secured from distortion or other injury.

Download Cut-and-bend Reinforcement Bars Brochure

Spacers: Spacer blocks must be arranged at regulars’ gap to support initial layers of reinforcement off the concrete blinding or bottom formwork. Spacers are attached safely to the reinforcement while arranging them. The number of spacers should be the least which are essential for keeping the reinforcement in its exact position. Spacers blocks must be of standard cement mortar or such other composition as sanctioned earlier by the Engineer. In slabs, if there are two or more layers of reinforcement, the upper layers of steel must be supported in position with steel chairs.

Lap Length for Reinforced Bar: Binding works (two ends coincided together) for reinforcement will consistent with designing requirements. There does not exist any binding points at the high-pressured or bending points. In the cross section of structure, the binding points should not surpass 25% of the total area of cross section for round bar as well as 50% for deformed bar.

- Application of concrete calculator

- Roofing Calculator can streamline the roof estimating process

- House construction cost calculator

- Engineering column design excel spreadsheet

- Material Estimating Sheet with Excel

- Materials List and Cost Estimate Worksheet

- Concrete Slab Estimating Calculator Sheet

- Common types of foundations for buildings

- Online calculation of construction materials

- Estimating with Excel for the Small Contractor

- Concrete Beam Design Spreadsheet

- Virtual Construction Management app for construction

- Autodesk’s Project Skyscraper

- Reed Construction’s Reed Insight

- Manage your construction project documentation

- Costimator, the popular cost estimating software

- On Center Software for construction professionals

- Free Construction Estimating Software

- Plumbing Calc Pro

- Cost Estimate Worksheet

- HVAC Piping Quantity Takeoff Worksheet

- Construction Estimating Software Sheet

- Estimate Cost Templates

- Construction Punch List

- Construction cost estimating template consisting estimating basic

- Gantt Chart Template for Excel

- Download Civil Engineering Spreadsheets with Verification

- The Building Advisor Estimating and Budgeting Worksheet

- Spreadsheet for design of concrete bridge

- Construction Estimating Software Free