How to test cement at site

- Concrete Cost Estimator

- Concrete Continuous Footing

- Landscape Bidding and Estimating

- Construction Cost Estimating

- Concrete and steel cost estimation

- Construction Cost Estimate Breakdown

- Construction Estimating Worksheet

- Home Construction Cost Estimate

- Estimate Pricing Sheet

- Sheet for General Contractor

- Construction Cost Estimate

- Labor Materials Cost Estimator

- Masonry Estimating Sheet

- Sheet for Building Contractor

- Construction Schedule Bar chart

- General Cost Estimator Sheet

- General Construction Estimate

- Building and Road Estimating Sheet

- Detailed expense estimates

- Door and Window Takeoff Sheet

- General Construction Cost Estimating Sheet

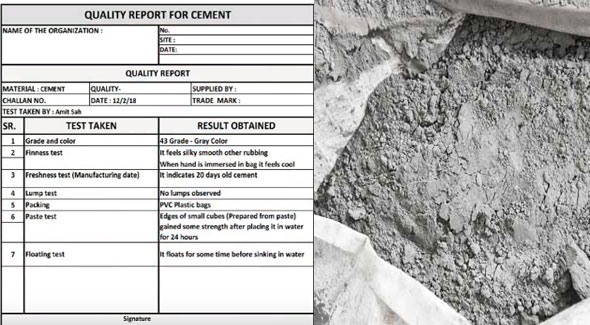

In order to verify the quality of cement in the jobsite, it becomes essential to carry out cement quality tests at a site within limited period of time.

In several situations, it becomes difficult to conduct any laboratory test in the short period of time. So, it is recommended to conduct the quality check by applying some elementary field tests.

Testing of cement :-

Standard consistency test, Fineness Test, Soundness Test, Strength Test, Field Testing

Field Testing: Open the bag of cement and takes a look to confirm whether there is any observable lumps in it. Such lumps are developed with the absorption of moisture from the atmosphere.

The color of cement should be consistent. It should contain typical cement color i.e. light greenish grey.

If thrusted, the feeling should be cool. If hydration reaction occurs inside the bag, it will turn into hot.

If you touch the cement, it should provide a smooth feeling rather than rough feeling. If the feeling is rough, it signifies adulteration with sand.

If the cement is thrown in a bucket engrossed in water, the particles should flow prior to sink.

If an inflexible paste of cement is made and cut with sharp edges and put on a glass plate below water, the shape of the cement will be unchanged and retain strength after 24 hours devoid of any cracking.

The smell of Cement Paste: A thin paste of cement with water should sense sticky among the fingers. If the cement includes in excess of pounded clay and silt as an adulterant, the paste will provide an earthy smell.

A 25mm × 25mm × 200mm (1”×1”×8”) block of cement with water is produced. The block is then drowned in water for three days. After extracting, it is supported 150mm separately and a weight of 15kg homogeneously placed over it. If it demonstrates no sign of failure the cement quality is good.

Video Source: Tutorials Tips

- Application of concrete calculator

- Roofing Calculator can streamline the roof estimating process

- House construction cost calculator

- Engineering column design excel spreadsheet

- Material Estimating Sheet with Excel

- Materials List and Cost Estimate Worksheet

- Concrete Slab Estimating Calculator Sheet

- Common types of foundations for buildings

- Online calculation of construction materials

- Estimating with Excel for the Small Contractor

- Concrete Beam Design Spreadsheet

- Virtual Construction Management app for construction

- Autodesk’s Project Skyscraper

- Reed Construction’s Reed Insight

- Manage your construction project documentation

- Costimator, the popular cost estimating software

- On Center Software for construction professionals

- Free Construction Estimating Software

- Plumbing Calc Pro

- Cost Estimate Worksheet

- HVAC Piping Quantity Takeoff Worksheet

- Construction Estimating Software Sheet

- Estimate Cost Templates

- Construction Punch List

- Construction cost estimating template consisting estimating basic

- Gantt Chart Template for Excel

- Download Civil Engineering Spreadsheets with Verification

- The Building Advisor Estimating and Budgeting Worksheet

- Spreadsheet for design of concrete bridge

- Construction Estimating Software Free