Pile Concreting – The detailed process and checklist

- Concrete Cost Estimator

- Concrete Continuous Footing

- Landscape Bidding and Estimating

- Construction Cost Estimating

- Concrete and steel cost estimation

- Construction Cost Estimate Breakdown

- Construction Estimating Worksheet

- Home Construction Cost Estimate

- Estimate Pricing Sheet

- Sheet for General Contractor

- Construction Cost Estimate

- Labor Materials Cost Estimator

- Masonry Estimating Sheet

- Sheet for Building Contractor

- Construction Schedule Bar chart

- General Cost Estimator Sheet

- General Construction Estimate

- Building and Road Estimating Sheet

- Detailed expense estimates

- Door and Window Takeoff Sheet

- General Construction Cost Estimating Sheet

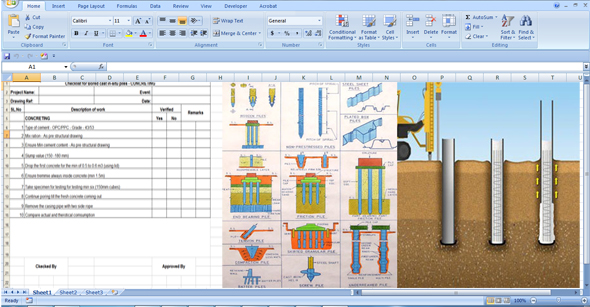

The concrete placing should not be started if compactness of fluid adjacent to the bottom of borehole surpasses 1250 kg/m3.

Recognition of the compactness of the drilling mud from the base of the borehole, should be accomplished by obtaining samples of fluid with appropriate liquid manure sample sanctioned by the engineer in charge, in initial few piles and at right space of piles subsequently and the results are recorded.

Once the flushing is finished, tremie head is eliminated and funnel is affixed to the tremie pipe.

The slump of the concrete is retained at 150 mm to 200 mm.

Concreting operation is accomplished with the 200 mm diameter trmie pipes.

Preliminary charge of concrete is provided in the funnel through a plug. Total concrete quantity in the funnel is over the volume of the whole pipe along with free space underneath the tremie. This will arrange a water-resistant concrete pouring via tremie.

Lifting and lowering is initiated frequently maintain adequate concrete in funnel all the time. With the progression of concreting, the tremie pipe should be eliminated sequentially, ensuring that the tremie pipe contains adequate embedment in the concrete unless the entire pipe is concreted. Adequate head of green concrete is arranged to avoid entry of soil or water into concrete. Positioning of concrete is a unceasing method from the toe level to top of pile

The concrete is poured in the funnel. As the concrete goes to the top of the funnel, the plug is upraised to facilitate the concrete to pour equivalent to the positioning of each batch of concrete.

Download Checklist for Bored Cast-In-Place Pile in PDF

Download Pile Concreting – The detailed process and checklist in Excel

The concreting of pile is accomplished up to minimum of 300 mm over the cut off level to obtain good and strong concrete at cut off level.

Ref: onlinecivilforum.com

Once the concreting tremie is finished, funnel and other accessories should be cleaned perfectly and retained lubricated in exact stacking condition adjacent to next pile location.

While organizing under water concreting, 10% extra cement over and above the design mix requirement is to be included in every batch.

- Application of concrete calculator

- Roofing Calculator can streamline the roof estimating process

- House construction cost calculator

- Engineering column design excel spreadsheet

- Material Estimating Sheet with Excel

- Materials List and Cost Estimate Worksheet

- Concrete Slab Estimating Calculator Sheet

- Common types of foundations for buildings

- Online calculation of construction materials

- Estimating with Excel for the Small Contractor

- Concrete Beam Design Spreadsheet

- Virtual Construction Management app for construction

- Autodesk’s Project Skyscraper

- Reed Construction’s Reed Insight

- Manage your construction project documentation

- Costimator, the popular cost estimating software

- On Center Software for construction professionals

- Free Construction Estimating Software

- Plumbing Calc Pro

- Cost Estimate Worksheet

- HVAC Piping Quantity Takeoff Worksheet

- Construction Estimating Software Sheet

- Estimate Cost Templates

- Construction Punch List

- Construction cost estimating template consisting estimating basic

- Gantt Chart Template for Excel

- Download Civil Engineering Spreadsheets with Verification

- The Building Advisor Estimating and Budgeting Worksheet

- Spreadsheet for design of concrete bridge

- Construction Estimating Software Free