Details of Rapid Hardening Cement (RHC) and its benefits

- Concrete Cost Estimator

- Concrete Continuous Footing

- Landscape Bidding and Estimating

- Construction Cost Estimating

- Concrete and steel cost estimation

- Construction Cost Estimate Breakdown

- Construction Estimating Worksheet

- Home Construction Cost Estimate

- Estimate Pricing Sheet

- Sheet for General Contractor

- Construction Cost Estimate

- Labor Materials Cost Estimator

- Masonry Estimating Sheet

- Sheet for Building Contractor

- Construction Schedule Bar chart

- General Cost Estimator Sheet

- General Construction Estimate

- Building and Road Estimating Sheet

- Detailed expense estimates

- Door and Window Takeoff Sheet

- General Construction Cost Estimating Sheet

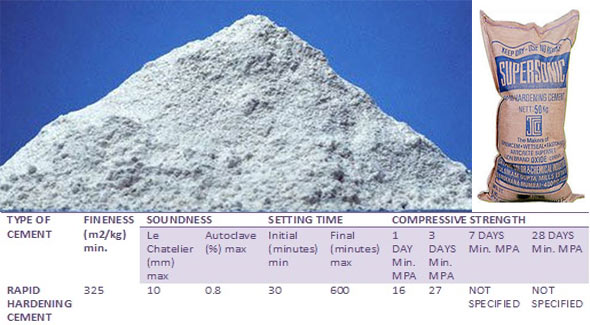

Rapid Hardening Cement (RHC) is also known as high early strength cement. The rapid hardening cement and ordinary portland cement is distinguished with the percentage of lime content.

Manufacturing: Rapid hardening cement is parched at a greater temperature as compared to that of the OPC under more controlled conditions.

Strength: The 3 days strength of rapid hardening cement is comparable with the 7 days strength of OPC when the water-cement ratio for both the cement is considered as equivalent. As greater percentage of tri-calcium silicate (C3S) is comprised in RHC together with finer grinding of the cement clinker, the rate of strength is inflated. Despite the fact that the rate at which RHC attains strength is greater as compared to the rate at which OPC attains strength, the ultimate strength is only a little higher for RHC.

Characteristics of RHC

a. Initial Setting Time: 30 minutes

b. Final Setting Time: 600 minutes

c. The specific surface is greater than 3250 cm2/gm.

d. RHC is lighter than OPC.

e. The curing period for RHC is less.

Application of RHC: Rapid hardening cement is frequently utilized in development of road where the traffic cannot be stopped for prolonged time period. RHC is also utilized where the formwork should have been eliminated before time for reuse. It is also suitable for those circumstances where adequate strength is necessary for further construction as quickly as practicable. These can also be applied for constructing precast slabs, posts, electric poles.

Benefits

a. It is cost-effective since the curing period for rapid hardening cement is minor

b. Shrinkage throughout curing and hardening of cement is minor in case of RHC.

c. RHC has good resistance strength against sulphur.

d. The speed of construction process is better since the strength is attained in considerably less time.

Drawbacks

a. It is high-priced as compared to Ordinary Portland Cement.

Extra Rapid Hardening Cement

Manufacturing: Intergrinding Calcium Chloride (CaCl2) with RHC, extra RHC can be produced. The proportion of calcium chloride throughout the manufacturing process should not surpass 3%.

Strength: Strength of Extra RHC is about 25 % greater than that of the RHC at 1-2 days whereas the strength is increased by only 10-20 % after 7 days.

Applications: Extra rapid hardening cement is effective for cold weather concreting.

- Application of concrete calculator

- Roofing Calculator can streamline the roof estimating process

- House construction cost calculator

- Engineering column design excel spreadsheet

- Material Estimating Sheet with Excel

- Materials List and Cost Estimate Worksheet

- Concrete Slab Estimating Calculator Sheet

- Common types of foundations for buildings

- Online calculation of construction materials

- Estimating with Excel for the Small Contractor

- Concrete Beam Design Spreadsheet

- Virtual Construction Management app for construction

- Autodesk’s Project Skyscraper

- Reed Construction’s Reed Insight

- Manage your construction project documentation

- Costimator, the popular cost estimating software

- On Center Software for construction professionals

- Free Construction Estimating Software

- Plumbing Calc Pro

- Cost Estimate Worksheet

- HVAC Piping Quantity Takeoff Worksheet

- Construction Estimating Software Sheet

- Estimate Cost Templates

- Construction Punch List

- Construction cost estimating template consisting estimating basic

- Gantt Chart Template for Excel

- Download Civil Engineering Spreadsheets with Verification

- The Building Advisor Estimating and Budgeting Worksheet

- Spreadsheet for design of concrete bridge

- Construction Estimating Software Free