Importance of Reinforcement Detailing of RCC Members

- Concrete Cost Estimator

- Concrete Continuous Footing

- Landscape Bidding and Estimating

- Construction Cost Estimating

- Concrete and steel cost estimation

- Construction Cost Estimate Breakdown

- Construction Estimating Worksheet

- Home Construction Cost Estimate

- Estimate Pricing Sheet

- Sheet for General Contractor

- Construction Cost Estimate

- Labor Materials Cost Estimator

- Masonry Estimating Sheet

- Sheet for Building Contractor

- Construction Schedule Bar chart

- General Cost Estimator Sheet

- General Construction Estimate

- Building and Road Estimating Sheet

- Detailed expense estimates

- Door and Window Takeoff Sheet

- General Construction Cost Estimating Sheet

The design engineer should be liable for ensuring the structural protection of the design, details, examining the shop drawing.

Detailing plays a vital role as exact detailing of engineering designs should be maintained for planning and engineering process since faulty connections or detailing lead to collapsing of the structure.

Detailing assures the perfect finishing of the structures as well as the safety of the structures.

Detailing is crucial for the steel structures and for the RCC members because it is the rendition of all the mathematical expression’s and equation’s results.

Regarding RCC members which are frequently utilized for the buildings, the detailing is segregated as the detailing for Slabs-with or without openings.(Rectangular, circular, non-rectangular-pyramid slab, triangular etc) found in balcony slab, loft slab, corner slab etc.

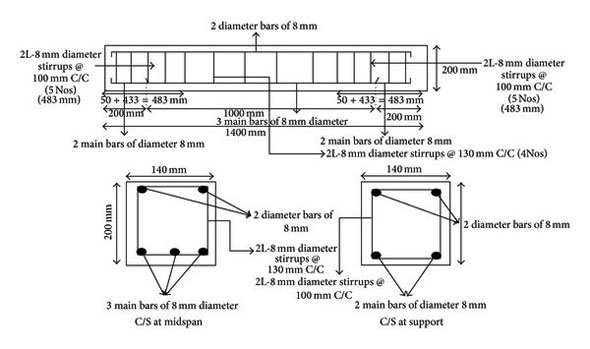

Beams – With or without openings.(Shallow & deep beams)

Columns – (Rectangular,l-shape,t-shape, circular,octagonal,cross shape etc)

Foundations - There is difference between the detailing for gravity loads and the lateral loads particularly for the seismic forces.

Besides, a different detailing is also found for the rehabilitation and strengthening of damaged structures.

Given below, some vital points about detailing :-

1. The drawing should be perfect & precise. When necessary, label each bar and illustrate its shape for transparency. Cross section of retaining wall that falls down instantly after providing soil backfill due to utilization of ¼” instead of 1-1/4” dia. Error is found as perfect rebar dia is covered by a dimension line.

Also Read: Some useful guidelines for structural detailing

2. When required, bar-bending schedule should be created.

3. Exact cover-clear cover, nominal cover or effective cover to reinforcement should be specified.

4. Determine the detailed location of opening/hole and provide sufficient details for reinforcements around the openings.

5. It is recommended to utilize the size of bars and spirals which are normally available. For a single structural member, the number of different sizes of bars should be retained minimum.

6. The grade of the steel should be evidently mentioned in the drawing.

7. There should not be hooks at the ends for the deformed bars.

8. Provide enlarged details at corners, intersections of walls, beams and column joint and at similar situations.

9. There should not be congestion of bars at points where members intersect and ensure that all reinforcement are arranged in a proper manner.

10. For bundled bars, lapped splice of bundled bars should be formed by splicing one bar at a time; such individual splices inside the bundle should be staggered.

11. Ensure to arrange hooked and bent up bars and they should have sufficient concrete protection.

12. Specify all expansion, construction and contraction joints on plans and give details for such joints.

13. The position of construction joints should be provided at the point of minimum shear just about at mid or near the mid points. It should be created vertically and not in a sloped manner.

- Application of concrete calculator

- Roofing Calculator can streamline the roof estimating process

- House construction cost calculator

- Engineering column design excel spreadsheet

- Material Estimating Sheet with Excel

- Materials List and Cost Estimate Worksheet

- Concrete Slab Estimating Calculator Sheet

- Common types of foundations for buildings

- Online calculation of construction materials

- Estimating with Excel for the Small Contractor

- Concrete Beam Design Spreadsheet

- Virtual Construction Management app for construction

- Autodesk’s Project Skyscraper

- Reed Construction’s Reed Insight

- Manage your construction project documentation

- Costimator, the popular cost estimating software

- On Center Software for construction professionals

- Free Construction Estimating Software

- Plumbing Calc Pro

- Cost Estimate Worksheet

- HVAC Piping Quantity Takeoff Worksheet

- Construction Estimating Software Sheet

- Estimate Cost Templates

- Construction Punch List

- Construction cost estimating template consisting estimating basic

- Gantt Chart Template for Excel

- Download Civil Engineering Spreadsheets with Verification

- The Building Advisor Estimating and Budgeting Worksheet

- Spreadsheet for design of concrete bridge

- Construction Estimating Software Free