Step-by-step processes for developing a column

- Concrete Cost Estimator

- Concrete Continuous Footing

- Landscape Bidding and Estimating

- Construction Cost Estimating

- Concrete and steel cost estimation

- Construction Cost Estimate Breakdown

- Construction Estimating Worksheet

- Home Construction Cost Estimate

- Estimate Pricing Sheet

- Sheet for General Contractor

- Construction Cost Estimate

- Labor Materials Cost Estimator

- Masonry Estimating Sheet

- Sheet for Building Contractor

- Construction Schedule Bar chart

- General Cost Estimator Sheet

- General Construction Estimate

- Building and Road Estimating Sheet

- Detailed expense estimates

- Door and Window Takeoff Sheet

- General Construction Cost Estimating Sheet

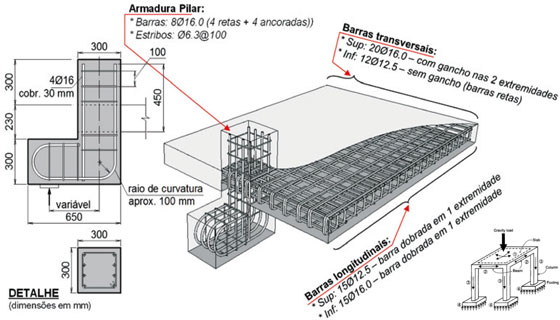

Construction of a column

Vertical Reinforcement: A rectangular column should contain minimum 4 reinforcements at 4 corners.

Circular Column in Reinforcement: Circular column should contain at least 6 reinforcements.

The highest reinforcement should be 8% and lowest reinforcement should be 1%.

Overlapping of Rods: It is performed if the length of reinforcement bar is small but bigger reinforcement is essential.

Arranged in mid span

Affixed with hooks

Ties: Column contains closed lateral ties which are arranged equivalently over the column.

Withstand shear force and bursting out effect.

Bars having different types of diameters like 10 mm, 12 mm are applied.

Positioning of Ties:

Normal spacing = S in mid span

Gapping near support joint = S/2

Hooks: The objective of hooks is to withstand enlargement.

The hooks should have been curved at 135 degree.

Formwork: It should have resistance capacity against leak. It has smooth inside and it should be arranged perfectly.

Minimum clear cover in formwork should be 1.5.

Casting in Column: The casting in concrete is performed in two lifts. To get rid of concrete segregation, casting should not be performed from over 5 feet high.

Compaction & Removal of Formwork: Compaction is performed through vibrator.

To make superior bonding among new and old concrete, construction joints are utilized.

Elimination of formwork is done after 3 days.

Curing: In curing, water is arranged for hydration reaction.

Raise the strength up to 2.5 times.

Curing is accomplished for 21 days.

To make curing stronger, gunny bags are utilized.

Source: www.slideshare.net

- Application of concrete calculator

- Roofing Calculator can streamline the roof estimating process

- House construction cost calculator

- Engineering column design excel spreadsheet

- Material Estimating Sheet with Excel

- Materials List and Cost Estimate Worksheet

- Concrete Slab Estimating Calculator Sheet

- Common types of foundations for buildings

- Online calculation of construction materials

- Estimating with Excel for the Small Contractor

- Concrete Beam Design Spreadsheet

- Virtual Construction Management app for construction

- Autodesk’s Project Skyscraper

- Reed Construction’s Reed Insight

- Manage your construction project documentation

- Costimator, the popular cost estimating software

- On Center Software for construction professionals

- Free Construction Estimating Software

- Plumbing Calc Pro

- Cost Estimate Worksheet

- HVAC Piping Quantity Takeoff Worksheet

- Construction Estimating Software Sheet

- Estimate Cost Templates

- Construction Punch List

- Construction cost estimating template consisting estimating basic

- Gantt Chart Template for Excel

- Download Civil Engineering Spreadsheets with Verification

- The Building Advisor Estimating and Budgeting Worksheet

- Spreadsheet for design of concrete bridge

- Construction Estimating Software Free