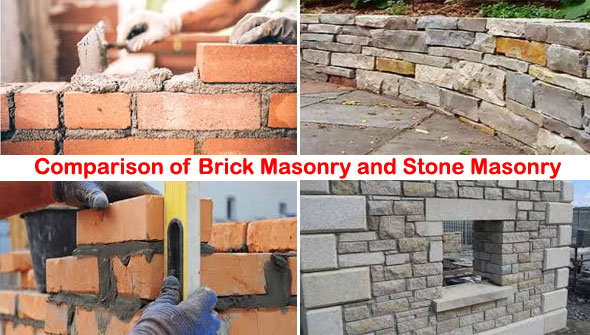

Difference between stone masonry and brick masonry

- Concrete Cost Estimator

- Concrete Continuous Footing

- Landscape Bidding and Estimating

- Construction Cost Estimating

- Concrete and steel cost estimation

- Construction Cost Estimate Breakdown

- Construction Estimating Worksheet

- Home Construction Cost Estimate

- Estimate Pricing Sheet

- Sheet for General Contractor

- Construction Cost Estimate

- Labor Materials Cost Estimator

- Masonry Estimating Sheet

- Sheet for Building Contractor

- Construction Schedule Bar chart

- General Cost Estimator Sheet

- General Construction Estimate

- Building and Road Estimating Sheet

- Detailed expense estimates

- Door and Window Takeoff Sheet

- General Construction Cost Estimating Sheet

Brick Masonry: For brick masonry work, the bricks are provided in the mortar in a structured manner to retain proper load bearing strength to resist extreme loads.

Several types of bricks and mortars are utilized for brick masonry production.

The joints among the bricks should be filled properly with appropriate mortar to maintain the strong bonding in brick masonry.

Brick Work: Brickwork with approved machine made bricks in perfect line and level, finishes including wetting the brick, packing the joints and curing the work complete in all types of walls, columns etc.

In cement sand mortar (1: 4)

In cement sand mortar (1:6)

Bricks shall be laid in English bond. If the Supervision Team instructs, the brickwork shall be done in Flemish bond without extra cost. Beds of course should be as nearly perpendicular as possible to the line of pressure. A systematic bond must be maintained throughout the whole work and perpend must be continuous in alternate courses.

All bricks must be well bedded and all joints should be of uniform thickness. The Supervision Team reserves the right to reject any brick, which may have an injurious effect.

All courses shall be in true level and in perfect bond and filled with mortar to provide a thoroughly water resistant structure. All brick works should be vertical and true to line and level. No chipping or rubbing of the face shall be allowed. Half brick wall shall be reinforce~ if provisioned in B.O.Q., with 2 numbers 6mm M.S. bar laid horizontal after every five layers.

Stone Masonry: The erection of stones bonded together with mortar is defined as stone masonry.

Also Read: How to study the drawing of any stone masonry retaining wall

As the stones are easily accessible, they are considered as an cost-effective material for the construction of different building components like walls, columns, footings, arches, beams, etc..

Stone-masonry is stronger, long-lasting, and weather-resistant, with regard to brick masonry. It is mostly found in building up the piers, docks, dams lighthouse, and other marine structures.

Materials: Stones for masonry work in dry/cement mortar shall be clean, hard, un-weathered .The length of any stone shall not exceed three times its height and breadth shall not be less than 150 mm or greater than 3/4th of the thickness of the wall.

Spalls not exceeding 2 percent of the total surface area in plan of the wall may be used in a staggered pattern for filling voids between larger stones. Bond stones shall measure at least l50x150 mm on the exposed surface of the wall and the length at least 450 mm or the full thickness of the wall.

A minimum of 10% by volume of stone masonry work shall be of bond stones and the bond stone shall be proved at the rate of at least one in 0.8 m of the exposed face of the wall. The bond stones shall be hammered, chisel dressed and their bidding planes with natural bed shall be at right angles to the direction of the load.

Cement, sand, water and mortar will meet the standard requirement as specified for brickwork. No unbroken or round boulder will be used in masonry works. Stones for coursed random rubble masonry work: shall have broken faces on three sides. Samples of stones intended for use in the works shall be submitted to the Supervision Team for approval.

Laying: Dry stone masonry work will be constructed on the prepared foundation surface by laying large selected stones with their largest dimension in the horizontal plane. Stones shall be individually placed to break joints and to contain minimum voids and shall be bedded and bonded to adjoining stones. Spaces between large stones shall be filled with spalls securely rammed into place. Large stones shall not bear on the spalls top and sides of completed work shall be finished neatly and selected copingstones placed.

Stone masonry work in cement sand mortar shall be constructed in the same way as dry masonry with the exception that the stones should be wet and set in 1:4 or 1:3 cement sand mortar as specified. Exposed stone faces shall be cleaned of mortar by wire brushing.

The mortar shall be flushing pointed or as directed by the Supervision Team. Hand mixed mortar shall be of proper consistency, uniform in aluminum and workable. Plastering in between the joints of the stone will be allowed.

Measurement: The measurement shall be in cubic meters of the finished work.

- Application of concrete calculator

- Roofing Calculator can streamline the roof estimating process

- House construction cost calculator

- Engineering column design excel spreadsheet

- Material Estimating Sheet with Excel

- Materials List and Cost Estimate Worksheet

- Concrete Slab Estimating Calculator Sheet

- Common types of foundations for buildings

- Online calculation of construction materials

- Estimating with Excel for the Small Contractor

- Concrete Beam Design Spreadsheet

- Virtual Construction Management app for construction

- Autodesk’s Project Skyscraper

- Reed Construction’s Reed Insight

- Manage your construction project documentation

- Costimator, the popular cost estimating software

- On Center Software for construction professionals

- Free Construction Estimating Software

- Plumbing Calc Pro

- Cost Estimate Worksheet

- HVAC Piping Quantity Takeoff Worksheet

- Construction Estimating Software Sheet

- Estimate Cost Templates

- Construction Punch List

- Construction cost estimating template consisting estimating basic

- Gantt Chart Template for Excel

- Download Civil Engineering Spreadsheets with Verification

- The Building Advisor Estimating and Budgeting Worksheet

- Spreadsheet for design of concrete bridge

- Construction Estimating Software Free