How to validate the compressive strength of the concrete cube at jobsite

- Concrete Cost Estimator

- Concrete Continuous Footing

- Landscape Bidding and Estimating

- Construction Cost Estimating

- Concrete and steel cost estimation

- Construction Cost Estimate Breakdown

- Construction Estimating Worksheet

- Home Construction Cost Estimate

- Estimate Pricing Sheet

- Sheet for General Contractor

- Construction Cost Estimate

- Labor Materials Cost Estimator

- Masonry Estimating Sheet

- Sheet for Building Contractor

- Construction Schedule Bar chart

- General Cost Estimator Sheet

- General Construction Estimate

- Building and Road Estimating Sheet

- Detailed expense estimates

- Door and Window Takeoff Sheet

- General Construction Cost Estimating Sheet

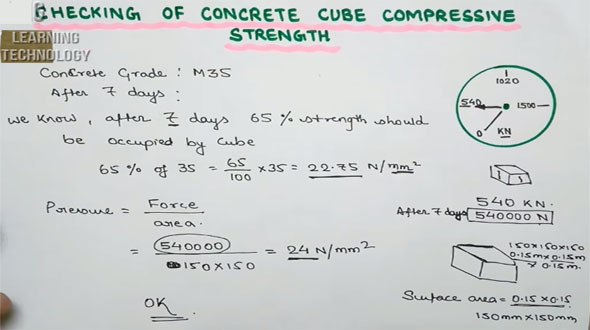

This construction video tutorial will teach you the process for validating the comprehensive strength of concrete cube.

Generally, we arrange various types of cubes for casting in the site. Then we check these cubes for 7 days, 14 days, 21 days, 28 days for finding out the exact percentage of comprehensive strength.

Compressive strength of concrete cube test sheds light on all the characteristics of concrete. This test method facilitates you to verify whether Concreting is done properly or not.

Compressive strength of concrete is affected by several factors like water-cement ratio, cement strength, quality of concrete material, quality control throughout production of concrete etc.

Test for compressive strength is performed either on cube or cylinder. Different types of standard codes are followed for concrete cylinder or concrete cube as the standard sample for the test.

Method: Compressive Strength Test of Concrete Cubes

For cube test, two types of samples either cubes of 15cm X 15cm X 15cm or 10cm X 10cm x 10cm based on the size of aggregate are utilized. Generally, cubical moulds of size 15cm x 15cm x 15cm are employed.

This concrete is poured in the mould and tempered perfectly in order that any void does not occur. These moulds are taken out after 24 hours and test specimens are transferred in water for curing. The top surface of these specimens should be prepared even and smooth. It is accomplished by laying cement paste and stretching smoothly on entire area of specimen.

With the help of compression testing machine, these specimens are examined after 7 days curing or 28 days curing. Load should be served slowly at the rate of 140 kg/cm2 per minute unless the Specimens fail. To obtain the compressive strength of concrete, load at the failure is divided by area of specimen.

To learn the complete process, watch the following video tutorial.

Video Source: L & T - Learning Technology

- Application of concrete calculator

- Roofing Calculator can streamline the roof estimating process

- House construction cost calculator

- Engineering column design excel spreadsheet

- Material Estimating Sheet with Excel

- Materials List and Cost Estimate Worksheet

- Concrete Slab Estimating Calculator Sheet

- Common types of foundations for buildings

- Online calculation of construction materials

- Estimating with Excel for the Small Contractor

- Concrete Beam Design Spreadsheet

- Virtual Construction Management app for construction

- Autodesk’s Project Skyscraper

- Reed Construction’s Reed Insight

- Manage your construction project documentation

- Costimator, the popular cost estimating software

- On Center Software for construction professionals

- Free Construction Estimating Software

- Plumbing Calc Pro

- Cost Estimate Worksheet

- HVAC Piping Quantity Takeoff Worksheet

- Construction Estimating Software Sheet

- Estimate Cost Templates

- Construction Punch List

- Construction cost estimating template consisting estimating basic

- Gantt Chart Template for Excel

- Download Civil Engineering Spreadsheets with Verification

- The Building Advisor Estimating and Budgeting Worksheet

- Spreadsheet for design of concrete bridge

- Construction Estimating Software Free