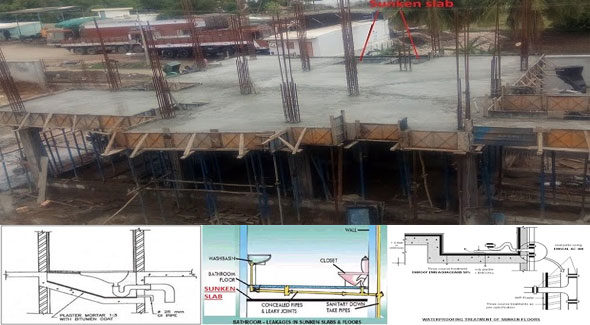

Sunken slab – Construction Process & Benefits

- Concrete Cost Estimator

- Concrete Continuous Footing

- Landscape Bidding and Estimating

- Construction Cost Estimating

- Concrete and steel cost estimation

- Construction Cost Estimate Breakdown

- Construction Estimating Worksheet

- Home Construction Cost Estimate

- Estimate Pricing Sheet

- Sheet for General Contractor

- Construction Cost Estimate

- Labor Materials Cost Estimator

- Masonry Estimating Sheet

- Sheet for Building Contractor

- Construction Schedule Bar chart

- General Cost Estimator Sheet

- General Construction Estimate

- Building and Road Estimating Sheet

- Detailed expense estimates

- Door and Window Takeoff Sheet

- General Construction Cost Estimating Sheet

A sunken slab is mainly provided to cover up or disguise drainage line and floor traps of a bath unit. The sunken slab is cast with a normal depth of 200 or 300 mm or any other based on the design.

This additional depth is utilized for arranging pipes and utility ducts. The sunken slabs are frequently utilized in the toilets, bathrooms and washing place.

Sunken slabs are chosen to be filled with light weight Expanded Clay Aggregate (ECA).

Given below, the construction process of a sunken slab :-

1. The concrete of the R.C.C. (floor and sunken slab) should be blended with a waterproofing material to obtain a solid, impermeable concrete.

2. Then cement and waterproofing material are diluted in water and sprinkled onto the RCC sunken slab. Then, a layer of plaster is arranged with a mortar plasticizer together with the cement mortar over the slab.

3. Brick are placed on the walls and plaster (prior to tiling) is done to the walls and floor with cement mortar blended with a mortar plasticizer.

4. Tile is secured with the floor and walls with non-shrink, water-resistant tile adhesives to protect the tiled area from water.

Also Read: Construction Cost Estimate Sheet

5. The sealants are used to seal the sanitary pipe joints. Sealants are made specially to seal sanitary joints securely to get rid of water leakage.

Benefits of sunken slab :-

All plumbing pipes are concealed within the slab.

The special plumbing fixtures are required to minimize noise at the time of using the bathroom.

To watch the complete tutorial, go through the following video.

Video Source: ArchiTech&Knowledge

- Application of concrete calculator

- Roofing Calculator can streamline the roof estimating process

- House construction cost calculator

- Engineering column design excel spreadsheet

- Material Estimating Sheet with Excel

- Materials List and Cost Estimate Worksheet

- Concrete Slab Estimating Calculator Sheet

- Common types of foundations for buildings

- Online calculation of construction materials

- Estimating with Excel for the Small Contractor

- Concrete Beam Design Spreadsheet

- Virtual Construction Management app for construction

- Autodesk’s Project Skyscraper

- Reed Construction’s Reed Insight

- Manage your construction project documentation

- Costimator, the popular cost estimating software

- On Center Software for construction professionals

- Free Construction Estimating Software

- Plumbing Calc Pro

- Cost Estimate Worksheet

- HVAC Piping Quantity Takeoff Worksheet

- Construction Estimating Software Sheet

- Estimate Cost Templates

- Construction Punch List

- Construction cost estimating template consisting estimating basic

- Gantt Chart Template for Excel

- Download Civil Engineering Spreadsheets with Verification

- The Building Advisor Estimating and Budgeting Worksheet

- Spreadsheet for design of concrete bridge

- Construction Estimating Software Free