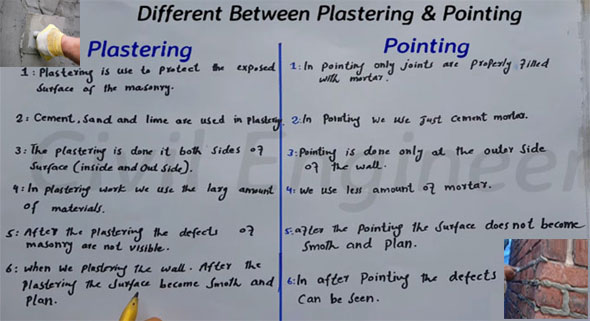

Variation among Plastering and Pointing

- Concrete Cost Estimator

- Concrete Continuous Footing

- Landscape Bidding and Estimating

- Construction Cost Estimating

- Concrete and steel cost estimation

- Construction Cost Estimate Breakdown

- Construction Estimating Worksheet

- Home Construction Cost Estimate

- Estimate Pricing Sheet

- Sheet for General Contractor

- Construction Cost Estimate

- Labor Materials Cost Estimator

- Masonry Estimating Sheet

- Sheet for Building Contractor

- Construction Schedule Bar chart

- General Cost Estimator Sheet

- General Construction Estimate

- Building and Road Estimating Sheet

- Detailed expense estimates

- Door and Window Takeoff Sheet

- General Construction Cost Estimating Sheet

PLASTERING: If mortar coats are used on the surfaces of walls, columns, ceiling etc. to bring smooth finish, it is known as plastering. Various types of mortars like lime mortar, cement mortar or lime-cement mortar are utilized for plastering.

For lime mortar, the proportion of fat lime to sand should be 1 : 3 or 1 : 4. For hydraulic lime, mix proportion (lime: sand) should be 1 : 2. Cement mortar of 1 : 4 or 1 : 6 mix is normally recognized for plastering, heavier mix is recommended for outside walls. To maintain the cost effectiveness of lime mortar and good quality of cement mortar, lime-cement mortar of proportion (cement : lime : sand) of 1 : 1 : 6 or 1 : 1 : 8 or 1 : 2 : 8 is suitable for application.

The purpose of plastering are given below:

1. To disguise damage workmanship

2. To provide smooth surface to get rid of catching of dust.

3. To provide good appearance.

4. To safeguard the wall from rain water and other atmospheric agencies.

5. To safeguard surfaces against vermit. Requirement of good plaster are:

1. It should abide by the background easily.

2. It should be strong and long lasting.

3. It should control penetration by moisture

4. It should be cost-effective.

Lime mortar is normally utilized in 3 coats whereas cement mortar is utilized in two or three coats for the stone and brick masonry. Toward concrete surfaces cement mortar should be used in two or three coats.

For concrete building blocks, only one coat of cement mortar should be used frequently.

The first coat offers means of obtaining level surface. The final coat offers smooth surface. If three coats are applied simultaneously second coat is termed as floating coat. The average thickness of first coat is 10 to 15 mm. Middle coat thickness is 6–8 mm. The final coat is just 2 to 3 mm thick. For single coat, thickness is maintained among 6 to 12 mm. Such coats are applied on concrete surfaces which are not uncover to rain.

POINTING: Rather than plastering whole surface of the masonry, special mortar finishing work is accomplished to the uncovered joints. It is known as pointing. It comprises of raking the joints to a depth of 10 mm to 20 mm and fill it with thicker mortar mixes. For lime mortar, pointing mix should utilized as 1 : 2 and for cement mortar, pointing mix should be applied as 1 : 3.

Pointing is effective for stone masonry as stones contain elegant colours and good resistance capacity against water penetration. Pointing makes the weaker part of masonry (i.e. to joints) perfect and enhances the artistic view of the masonry.

- Application of concrete calculator

- Roofing Calculator can streamline the roof estimating process

- House construction cost calculator

- Engineering column design excel spreadsheet

- Material Estimating Sheet with Excel

- Materials List and Cost Estimate Worksheet

- Concrete Slab Estimating Calculator Sheet

- Common types of foundations for buildings

- Online calculation of construction materials

- Estimating with Excel for the Small Contractor

- Concrete Beam Design Spreadsheet

- Virtual Construction Management app for construction

- Autodesk’s Project Skyscraper

- Reed Construction’s Reed Insight

- Manage your construction project documentation

- Costimator, the popular cost estimating software

- On Center Software for construction professionals

- Free Construction Estimating Software

- Plumbing Calc Pro

- Cost Estimate Worksheet

- HVAC Piping Quantity Takeoff Worksheet

- Construction Estimating Software Sheet

- Estimate Cost Templates

- Construction Punch List

- Construction cost estimating template consisting estimating basic

- Gantt Chart Template for Excel

- Download Civil Engineering Spreadsheets with Verification

- The Building Advisor Estimating and Budgeting Worksheet

- Spreadsheet for design of concrete bridge

- Construction Estimating Software Free