Details of Concrete Edge Restraint

- Concrete Cost Estimator

- Concrete Continuous Footing

- Landscape Bidding and Estimating

- Construction Cost Estimating

- Concrete and steel cost estimation

- Construction Cost Estimate Breakdown

- Construction Estimating Worksheet

- Home Construction Cost Estimate

- Estimate Pricing Sheet

- Sheet for General Contractor

- Construction Cost Estimate

- Labor Materials Cost Estimator

- Masonry Estimating Sheet

- Sheet for Building Contractor

- Construction Schedule Bar chart

- General Cost Estimator Sheet

- General Construction Estimate

- Building and Road Estimating Sheet

- Detailed expense estimates

- Door and Window Takeoff Sheet

- General Construction Cost Estimating Sheet

Tensile stresses may occur when the movement (expansion and/or contraction) is restrained inside a young concrete constituent. As a result, cracking is inevitable. This restrained to movement is generally defined as restraint.

Restraints are categorized as internal or external to the constituent. Due to dissimilar temperature variations inside a mass concrete element, the internal restraints take place and it can lead to surface and/or internal cracking. Although, it is only applicable to very thick sections (1000 mm or more).

External restraints occur because of the support/casting condition of the concrete. The external restraints are categorized as follow :

(1) End restraints

(2) Edge restraints

End restraint: End restraints happen if the edges of a young concrete are obstructed from movement. It is normally found in suspended slab cast among rigid cores, walls or columns, in infill bays, ground slab cast on piles, large area ground slabs restrained locally, e.g. by piles, columns or column foundations or by the formation of friction, walls cast against secant, contiguous concrete or steel sheet piled walls etc (CIRIA C660).

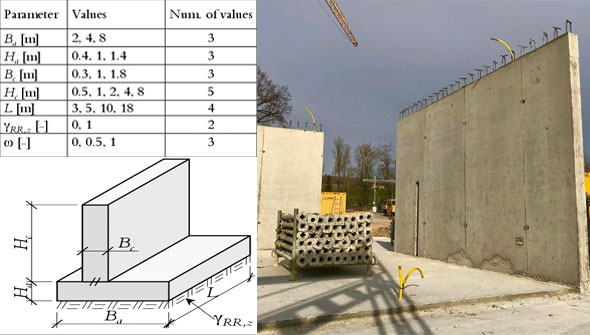

Edge restraint: It usually happens where the young concrete section (suppose a wall) is cast on a solidified concrete base i.e. the restriction remains only in one direction, and the interaction exists among the old and new concrete with regards to distribution of cracks. There is difference between edge restraint and end restraint since the crack width belongs to a function of restrained strain instead of the tensile capacity of the concrete.

Sometimes, there is combination of end restraint and edge restraint.

Restraint Factors: The level of restraint in a young concrete caused by adjacent element is usually defined with restraint factors.

Also Read: Download RC elements analysis and design spreadsheet

The degree of restraint, R, is normally taken as the ratio among the actual stress in a contracting body and the stress introduced under full restraint.

Degree of restraint R = Actual imposed stress / Imposed stress at full restraint

It is complicated to find out the degree of restraint appropriately, but it is essential to find restraint factors which are perfect as much as possible. In accordance with CIRIA C660, the restraint factors introduced by BS 8110-2 and HA BD 28/87 reveals perfect restraint values, whereas the restraint factors from BS 8007 and EN 1992-3 contains a modification factor of 0.5 to take into account creep under sustained loading.

ACI (1990) (cited by CIRIA C660) developed method for computing the edge restraint on the basis of the pertinent geometry and stiffness of the old and new concrete. The equation is provided as follow;

Restraint at the joint Rj = 1/(1 + AnEn/AoEo)

Here;

An denotes Cross-sectional area of the new (restrained) pour.

Ao denotes the cross-sectional area of the old concrete.

En denotes the modulus of elasticity of the new pour concrete.

Eo denotes the modulus of elasticity of the old concrete.

However, CIRIA C660 defines that the relative areas of influence of Ao and An can't be explained easily. So, the following simple rules should be followed;

I. For a wall cast at the edge of a slab (An/Ao) = (hn/ho) (thickness of new concrete/thickness of old concrete).

II. For wall cast remote from the edge of the slab (An/Ao) = (hn/2ho).

III. En/Eo ranges from 0.7 to 0.8 (but 0.8 is recommended).

- Application of concrete calculator

- Roofing Calculator can streamline the roof estimating process

- House construction cost calculator

- Engineering column design excel spreadsheet

- Material Estimating Sheet with Excel

- Materials List and Cost Estimate Worksheet

- Concrete Slab Estimating Calculator Sheet

- Common types of foundations for buildings

- Online calculation of construction materials

- Estimating with Excel for the Small Contractor

- Concrete Beam Design Spreadsheet

- Virtual Construction Management app for construction

- Autodesk’s Project Skyscraper

- Reed Construction’s Reed Insight

- Manage your construction project documentation

- Costimator, the popular cost estimating software

- On Center Software for construction professionals

- Free Construction Estimating Software

- Plumbing Calc Pro

- Cost Estimate Worksheet

- HVAC Piping Quantity Takeoff Worksheet

- Construction Estimating Software Sheet

- Estimate Cost Templates

- Construction Punch List

- Construction cost estimating template consisting estimating basic

- Gantt Chart Template for Excel

- Download Civil Engineering Spreadsheets with Verification

- The Building Advisor Estimating and Budgeting Worksheet

- Spreadsheet for design of concrete bridge

- Construction Estimating Software Free